Introduction to Viscosity Control

Viscosity is a fundamental property in the field of paints and coatings, referring to a fluid’s resistance to flow. In the context of paints, viscosity is crucial as it directly impacts application techniques, texture, and ultimately the finish on surfaces. Specifically, viscosity signifies how thick or thin a paint is, which dictates how easily it can be spread or sprayed. A higher viscosity indicates a thicker paint, while lower viscosity suggests a thinner consistency.

The importance of controlling viscosity in paint formulations cannot be overstated. Paints with optimal viscosity levels facilitate improved application processes. For example, a paint that is too viscous may lead to difficulties in spreading, resulting in an uneven coat, while excessively low viscosity may cause paint to drip and fail to adhere properly to surfaces. Therefore, achieving the right viscosity enhances the usability of the paint, ensuring smoother application and a high-quality finish.

Moreover, viscosity influences the texture and appearance of the final paint surface. Paints with controlled viscosity can create various effects, from smooth finishes to textured applications. Understanding the relationship between viscosity and paint formulation is essential for manufacturers like Mithila Paints, as it involves balancing factors such as pigment concentration, solvent mixtures, and additives to achieve desired outcomes. By mastering viscosity control, paint producers can not only improve the product’s performance but also meet the aesthetic preferences of customers.

In summary, viscosity is a pivotal property in paint technology, influencing everything from application ease to aesthetic results. Therefore, understanding and managing viscosity is key to producing high-quality paints that meet both functional and decorative requirements.

The Importance of Viscosity Control

Viscosity control plays a crucial role in the production of high-quality paints, influencing various physical properties that directly affect the paint’s performance. The viscosity of a paint affects its flow, leveling, and drying characteristics, all of which are essential factors for achieving the desired finish and application ease.

Firstly, viscosity impacts how paint behaves during application. A paint with optimal viscosity ensures an even flow and smooth application, preventing issues such as drips or uneven coverage. If the viscosity is too high, the paint may become challenging to apply, leading to clumps and an unsatisfactory aesthetic finish. Conversely, excessively low viscosity may cause the paint to run, resulting in an undesirable appearance and potential waste of material.

Furthermore, the leveling property of paint is significantly affected by viscosity. Proper viscosity allows the paint to self-level as it dries, creating a smooth surface free of brush or roller marks. This attribute is particularly vital in applications requiring a high gloss or durable finish. The right viscosity facilitates uniform film formation, allowing for an aesthetically pleasing result.

The drying properties of paint are also closely linked to viscosity. Each coating has an optimal viscosity range that supports efficient drying without compromising performance. If the viscosity is insufficient, the paint may dry too quickly, leading to a poor bond and potential peeling over time. Conversely, if the viscosity is too thick, it may take overly long to dry, delaying project completion.

In conclusion, effective viscosity control is paramount in paint production. By maintaining optimal viscosity levels, manufacturers can ensure the desired flow, leveling, and drying characteristics, which ultimately enhance the quality and performance of the final product. This meticulous attention to viscosity is essential for achieving superior finishes that meet consumer expectations.

Factors Affecting Viscosity

The viscosity of paint is a crucial property that significantly impacts its application and performance. Several factors play a pivotal role in determining this characteristic, with the primary influences being temperature, pressure, composition, and the presence of additives. Understanding these elements is essential for any manufacturer, including Mithila Paints, striving to achieve optimal viscosity control.

Temperature is one of the most influential factors affecting viscosity. As the temperature increases, the viscosity of a liquid generally decreases. This phenomenon occurs because heat reduces the intermolecular forces, allowing molecules to move more freely. Consequently, in higher temperatures, paint becomes thinner, enhancing its flow and leveling properties. Conversely, when the temperature drops, viscosity tends to increase, which can lead to difficulties in application and coverage. Thus, maintaining the appropriate temperature balance is vital during the paint production process.

Pressure also impacts paint viscosity, particularly during application processes such as spraying. An increase in pressure can lead to a reduction in viscosity, facilitating smoother application, while lower pressure may increase viscosity, resulting in challenges with atomization and coverage. Manufacturers must consider this factor, especially in automated spraying systems.

The composition of paint—including pigments, binders, and solvents—significantly influences its viscosity. Pigments can alter fluid dynamics; finer pigments may promote higher viscosity, while coarser ones can lower it. Binders, which help in film formation, also contribute to viscosity; for example, high molecular weight binders typically enhance thickness. Similarly, solvents are added to adjust viscosity according to desired application methods.

Lastly, the inclusion of additives such as thickeners or surfactants can further modify paint viscosity. Thickeners enhance viscosity for specific applications, while surfactants can reduce surface tension, improving overall flow and spreadability. In summary, a comprehensive understanding of these factors allows manufacturers like Mithila Paints to effectively control viscosity, leading to improved product quality and performance.

Viscosity Measurement Techniques

In the paint manufacturing industry, precise viscosity measurement is crucial for ensuring the quality and performance of the final product. Various techniques and instruments are utilized to gauge viscosity effectively, with viscometers and rheometers being the most common tools. Each method has distinct advantages, making it essential to select the appropriate one based on specific paint formulation and application requirements.

Viscometers, which measure the flow of a liquid, come in various types, including rotatory, capillary, and falling ball viscometers. Rotary viscometers are widely used in the industry due to their ability to assess viscosity under different shear rates. They provide reliable measurements across a spectrum of paint types and formulations. Meanwhile, capillary viscometers are favored for their simplicity and accuracy in low-viscosity fluids. The choice among these tools often depends on the paint’s consistency and the desired flow characteristics.

On the other hand, rheometers offer more comprehensive insights by measuring how materials flow under various conditions. They are particularly advantageous for complex paint systems that exhibit non-Newtonian behavior, where viscosity changes with shear rate. Different types of rheometers, such as dynamic and static rheometers, allow for a thorough analysis of a paint’s flow properties, helping manufacturers tailor formulations to meet application standards. When deciding on a viscosity measurement technique, one must consider factors like the paint’s chemical composition, the required viscosity range, and the testing environment to ensure optimal results.

Ultimately, achieving precise viscosity control at Mithila Paints hinges upon selecting the right measurement method. By understanding the capabilities and limitations of each technique, manufacturers can ensure consistency and reliability in their paint products, contributing to overall quality and performance.

Mithila Paints’ Approach to Viscosity Control

Mithila Paints employs a meticulous methodology in addressing viscosity control throughout its production processes. Understanding that viscosity significantly influences the application and performance of paint, the company implements standardized procedures coupled with cutting-edge technology to ensure consistency. The management of viscosity is not only pivotal for product quality but also essential for customer satisfaction and operational efficiency.

The company utilizes state-of-the-art viscometers to accurately measure the viscosity of various formulations during production. These instruments allow for real-time monitoring and adjustments, facilitating precise control over the final product characteristics. By establishing specific viscosity ranges for each product line, Mithila Paints can maintain uniformity across its extensive array of paints and coatings. Moreover, rigorous testing protocols are enforced, where samples undergo thorough analysis before reaching the market.

Innovation plays a fundamental role in Mithila Paints’ approach to viscosity control. The use of advanced mixing technologies helps achieve optimal distribution of raw materials, which in turn supports the uniformity of viscosity. These technologies are complemented by the developing of proprietary formulations that enhance the stability of paint while ensuring ease of application. The research and development team continually seeks new ingredients and methods, striving to improve the overall performance of their products.

Training and development of personnel also constitute a vital aspect of Mithila Paints’ viscosity control strategy. Employees are educated on the importance of viscosity in determining paint application methods and performance. By promoting a culture of quality consciousness, the company can empower its workforce to yield top-tier products that meet market demands effectively.

In summary, Mithila Paints’ commitment to meticulous viscosity control is evident in the integration of technology, precise procedures, and ongoing innovations, ensuring that its paint products consistently meet high standards of quality and performance.

Additives for Viscosity Modification

In the realm of paint formulations, the control of viscosity is paramount for ensuring both application performance and final product quality. At Mithila Paints, a range of additives plays a pivotal role in viscosity modification, providing formulators with the flexibility to tailor products according to specific application requirements. The main types of additives utilized for this purpose include thickeners and thinners, each serving distinct functions in altering the viscosity of paint mixtures.

Thickeners are substances that increase the viscosity of a fluid without significantly altering its other properties. Commonly employed thickeners include cellulose derivatives, such as hydroxyethyl cellulose, as well as synthetic options like polyacrylic acids. These thickeners work by enhancing the intermolecular attractions within the paint formulation, thereby creating a gel-like consistency that facilitates better brushability and flow characteristics during application. At Mithila Paints, thickeners are chosen based on the desired thickness and application method, ensuring optimal performance under various conditions.

On the other hand, thinners are additives that decrease viscosity, allowing for smoother application and better coverage. Solvents such as mineral spirits and various esters are often used as thinners in paint formulations. These substances function by disrupting the network of polymer chains in the paint, effectively reducing the thickness of the mixture. When employed judiciously, thinners can improve levelling and drying times, making them essential in achieving a quality finish. Mithila Paints emphasizes the delicate balance between thinners and thickeners, as the right combination ensures that paints meet stringent user requirements and industry standards.

Through an in-depth understanding of these additives, Mithila Paints consistently formulates paints that excel in performance while maintaining controlled viscosity levels, underscoring the importance of additives in modern paint technology.

Challenges in Viscosity Management

Viscosity control is a critical aspect of paint manufacturing, as it directly impacts the performance, application, and ultimate finish of the product. However, managing viscosity presents several challenges for manufacturers like Mithila Paints. One of the primary issues arises from variations in raw materials. The quality and type of pigments, binders, solvents, and additives can significantly influence viscosity. Even minor discrepancies in these materials can lead to substantial differences in the final product’s flow characteristics, creating inconsistencies that can affect application and durability.

In addition to raw material variability, environmental conditions also play a crucial role in viscosity management. Temperature and humidity fluctuations in the production environment can alter the viscosity of paint formulations. For instance, lower temperatures can increase viscosity, making the paint thicker and more challenging to apply, while higher temperatures can decrease it, potentially leading to issues such as sagging during application. Mithila Paints addresses this challenge through stringent quality controls and by maintaining a stable production environment, ensuring that temperature and humidity levels are consistently monitored and adjusted as necessary.

Another significant challenge surfaces when addressing varying production scales. Small batch sizes may allow for more meticulous viscosity control, but as production scales up, maintaining consistency become increasingly complex. Differences in mixer speed, batch timing, or even material integration can introduce variations in viscosity. To counteract this, Mithila Paints employs advanced mixing technology and automated monitoring systems, which allow the team to account for scale changes while ensuring that viscosity remains within a targeted range.

Through a proactive approach to these challenges, Mithila Paints has developed a robust framework for viscosity control, emphasizing quality assurance and the continual refinement of processes. This strategic management of viscosity not only enhances product performance but also reinforces their commitment to delivering high-quality paint solutions to customers.

Future Trends in Viscosity Control

The landscape of viscosity control in paint production is evolving rapidly, driven by advancements in technology and an increasing demand for precision. One of the most significant trends is the integration of smart manufacturing technologies. This approach utilizes the Internet of Things (IoT) to create interconnected systems that allow for real-time monitoring and adjustments in viscosity levels. By employing smart sensors, manufacturers can continuously track the rheological properties of paint mixtures, ensuring that they meet desired specifications throughout the production process.

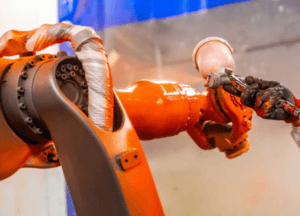

Automation is another crucial trend reshaping the viscosity control landscape. Automated systems reduce human error and enhance consistency by employing algorithms to adjust mixing processes dynamically. This results in a more efficient production line, where viscosity can be fine-tuned instantly based on real-time data. Furthermore, robotic systems can manage multiple batches simultaneously, leading to increased productivity and minimized downtime in paint manufacturing operations.

In addition to smart manufacturing and automation, the role of artificial intelligence (AI) in viscosity monitoring is poised to become more prominent. AI-powered tools can analyze vast amounts of data to predict how different materials will interact, thus optimizing formulations before production begins. This predictive capability allows manufacturers to experiment with new ingredients and formulations in a virtual environment, significantly reducing the time and resources required for trial and error in the lab.

Moreover, as sustainability becomes a stronger focus within the industry, viscosity control technologies are expected to advance in ways that reduce waste and improve resource efficiency. Innovations in viscosity measurements can lead to the development of environmentally friendly formulations that maintain performance without compromising on quality.

As these trends continue to develop, the future of viscosity control at companies like Mithila Paints promises to be characterized by greater efficiency, enhanced product quality, and a commitment to sustainability, positioning the industry for impactful advancements.

Conclusion

In the realm of paint manufacturing, mastering viscosity control is crucial for ensuring product performance and meeting customer expectations. At Mithila Paints, we recognize that the viscosity of our paints is not merely a technical specification; it plays a pivotal role in determining how our products perform in various applications. A well-regulated viscosity affects aspects such as flow, application ease, and the overall finish of the painted surface. With the correct viscosity, our paints exhibit optimal coverage and adherence qualities, which are essential for delivering high-quality results.

Mithila Paints is committed to maintaining the highest standards of quality and innovation. We continuously refine our processes to enhance viscosity control, utilizing state-of-the-art technology and expert knowledge. Our teams work diligently to select the right formulation and additives, ensuring that every batch of paint meets our stringent quality benchmarks. This commitment extends beyond product formulation; it embodies our dedication to customer satisfaction, as we strive to deliver paints that meet the diverse needs of our clientele.

Furthermore, the interconnectedness of viscosity with product performance highlights the importance of ongoing research and development in the paint industry. By prioritizing viscosity control, Mithila Paints not only enhances the functionality of our products but also reinforces our reputation as a leader in the sector. As we advance into the future, we will continue to innovate and optimize our formulations, ensuring that our paints provide exceptional value and performance to our customers. Ultimately, our focus on mastering viscosity control will empower us to meet the ever-evolving demands of the market while upholding our commitment to excellence.