Introduction to Epoxy Coatings

Epoxy coatings are a sophisticated blend of resin and hardener that form a complex polymer structure, resulting in a highly durable and resilient surface. The primary composition consists of an epoxy resin and a polyamine hardener, which, when mixed, initiate a chemical reaction that transforms the liquid components into a solid-state material. This transformation process, known as curing, enables the epoxy coating to form a strong, protective, and abrasion-resistant layer.

The versatility of epoxy coatings makes them invaluable across numerous sectors, including industrial manufacturing, automotive, aerospace, and residential flooring. One of the significant advantages of epoxy is its formidable chemical resistance, which provides robust protection against exposure to harsh chemicals, oils, and acids. Moreover, its exceptional adhesion properties ensure that the coating binds well to various substrates, including metals, concrete, and wood.

Additionally, epoxy coatings offer superior mechanical properties, such as impact resistance and high tensile strength. This makes them ideal for environments subject to heavy wear and tear. These coatings can withstand significant stress without compromising their structural integrity, ensuring a prolonged lifespan for the surfaces they protect.

Beyond durability, epoxy coatings also contribute aesthetic value. They come in a variety of colors and finishes, allowing for customization to suit specific design preferences. This makes them a popular choice not only for industrial applications but also for residential and commercial settings where both performance and appearance are critical.

In essence, epoxy coatings provide a multifaceted solution that combines strength, durability, and visual appeal. They protect surfaces from physical and chemical damage while enhancing their appearance, underscoring their broad utility in various applications.

The Science Behind Epoxy Coatings

Epoxy coatings represent one of the most durable and versatile classes of protective coatings, primarily due to their unique chemical makeup and the sophisticated technology employed in their formulation. At its core, epoxy coating is a thermosetting polymer that forms a highly stable, rigid network when it undergoes curing. This curing process is a chemical reaction between the two main components of the coating: the epoxy resin and a curing agent or hardener.

Epoxy resins come in various types, tailored for distinct applications. The most commonly used resins include bisphenol A (BPA) and bisphenol F (BPF) epoxies, each offering specific advantages. BPA-based epoxies are known for their excellent mechanical and thermal properties, making them ideal for heavy-duty purposes. Conversely, BPF-based epoxies exhibit superior chemical resistance and lower viscosity, which enhances their ease of application.

When the epoxy resin is mixed with the curing agent, a complex chemical reaction known as polymerization takes place, leading to cross-linking, where multiple molecular chains interconnect. This cross-linking imparts the epoxy coating its tough, stable, and highly adhesive properties. The extent and nature of this cross-linking can be influenced by several factors, including the ratio of resin to hardener, the presence of additives, and the environmental conditions during curing, such as temperature and humidity.

Moreover, the versatility of epoxy coatings is partly attributed to their ability to bond with a variety of substrates. Whether applied to concrete, metals, or wood, epoxy coatings exhibit extraordinary adhesion, thanks to the chemical bonds formed at the interface between the coating and the substrate. These bonds are primarily responsible for the enhanced protective qualities, ensuring resistance to wear, impact, and corrosion, thereby prolonging the life of the coated material.

Technological advancements have further expanded the utility of epoxy coatings. Innovations such as modified epoxy resins, hybrid coatings, and environmentally friendly formulations have broadened the scope and applications of these coatings, ranging from industrial flooring and marine environments to everyday household items.

Benefits of Using Epoxy Coatings

Epoxy coatings offer a myriad of advantages that make them an attractive choice for both industrial and residential applications. One of their most notable benefits is their exceptional durability. These coatings create a robust, long-lasting surface that withstands the test of time, making them ideal for high-traffic areas. This durability is particularly beneficial in settings such as warehouses, factories, and garages, where the flooring must endure constant wear and tear.

Another significant advantage of epoxy coatings is their resistance to chemicals and abrasion. This characteristic ensures that the surfaces remain intact and unblemished even when exposed to harsh chemicals or frequent mechanical stress. Industries that frequently deal with chemicals, such as pharmaceutical manufacturing and automotive sectors, often rely on epoxy coatings to maintain a safe and clean environment.

Maintenance is another area where epoxy coatings shine. Their seamless and non-porous nature makes them incredibly easy to clean and maintain, reducing the time and effort required for upkeep. Spills and stains can be effortlessly wiped away, making these coatings a practical choice for hospitals, schools, and kitchens, where hygiene is paramount.

Aesthetically, epoxy coatings are highly versatile. They come in a wide array of colors and finishes, allowing for customization to meet specific design preferences. Whether aiming for a sleek, modern look or incorporating company branding into the floor design, epoxy coatings offer unlimited possibilities. This aesthetic flexibility enhances the appeal of commercial spaces, retail establishments, and even residential homes.

Real-life applications and testimonials further underscore the benefits of epoxy coatings. For instance, a local manufacturing plant in Mithila Paints reported a significant reduction in maintenance costs and downtime after switching to epoxy-coated floors. Similarly, homeowners have praised the enhanced appearance and simplified cleaning process offered by these coatings.

Overall, the combination of durability, chemical and abrasion resistance, ease of maintenance, and aesthetic appeal makes epoxy coatings a highly advantageous choice for a wide range of applications, highlighting their value and effectiveness in various settings.

Applications of Epoxy Coatings

Epoxy coatings have become a preferred solution across various industries due to their durability, resistance to chemicals, and versatility. One of the most prevalent applications of epoxy coatings is in industrial flooring. Factories, warehouses, and manufacturing plants benefit significantly from epoxy flooring because it provides a tough, long-lasting surface that can withstand heavy machinery, frequent foot traffic, and spills of industrial chemicals.

In addition to industrial settings, epoxy coatings are favored for garage floors. Homeowners and commercial developers use them to create a sleek, easy-to-clean surface that resists oil stains and tire marks. This not only enhances the aesthetic appeal of the garage but also prolongs the floor’s lifespan.

Countertops represent another domain where epoxy coatings excel. In both residential and commercial kitchens, epoxy-coated countertops offer a hygienic, smooth, and waterproof surface. They resist heat and can be customized to mimic the appearance of more expensive materials like marble or granite.

The automotive industry also utilizes epoxy coatings extensively. These coatings provide vehicles with robust defense against corrosion, abrasion, and chemicals, thereby extending the lifespan and maintaining the aesthetic quality of automotive parts. Epoxy coatings are commonly applied to car underbodies, truck beds, and even on certain internal components.

Marine applications are yet another sector where epoxy coatings are indispensable. Boats and ships face continuous exposure to harsh, saline environments, making it imperative to use materials that can withstand such conditions. Epoxy coatings deliver necessary protection against water ingress, rust, and the growth of marine organisms, ensuring the structural integrity and longevity of maritime vessels.

In conclusion, epoxy coatings are a versatile and durable solution applicable in various environments and industries. From enhancing industrial floors and garage aesthetics to protecting vehicles and marine vessels, the efficacy of epoxy coatings is evident. Each application highlights their ability to provide robust, long-lasting surfaces resistant to various forms of damage, illustrating why they are a popular choice in many different settings.

Why Choose Mithila Paints for Epoxy Coatings

When evaluating options for epoxy coatings, Mithila Paints stands out for a multitude of reasons that collectively highlight their commitment to quality and customer satisfaction. The company boasts a sterling reputation in the industry, built upon years of delivering top-notch products and services. Their epoxy coatings are synonymous with durability, resistance, and aesthetic appeal, qualities that are critical for both residential and commercial applications.

One of the core strengths of Mithila Paints is the exceptional quality of their epoxy products. Each batch is meticulously formulated to ensure optimal performance and longevity, adhering to stringent industry standards. The variety of epoxy coatings available from Mithila Paints is extensive, catering to a wide range of needs. From UV-resistant epoxies to those designed for high-traffic areas, they offer tailored solutions that meet specific requirements, ensuring that each project achieves its desired outcome.

Customer service is another area where Mithila Paints excels. They provide comprehensive support throughout the entire process—from selection and application to maintenance guidance. Their team of experts is always ready to offer professional advice, helping customers make informed decisions that best fit their particular needs. This commitment to service ensures that clients not only receive high-quality products but also the support necessary to utilize them effectively.

Innovative technologies are also a hallmark of Mithila Paints’ epoxy offerings. The company invests in research and development to consistently bring advanced solutions to market. Features like quick-drying formulations, enhanced adhesion properties, and eco-friendly components are integrated into their products, aligning with modern demands and environmental considerations. These innovations set Mithila Paints apart, providing a competitive edge in the field of epoxy coatings.

In conclusion, Mithila Paints is a preferred choice for epoxy coatings due to its reputable background, superior product quality, excellent customer service, and commitment to innovation. These attributes collectively ensure that clients receive value-added solutions that stand the test of time.

Step-by-Step Guide to Applying Epoxy Coatings

Applying epoxy coatings is a meticulous process that, when done correctly, ensures durable and appealing results. Before embarking on this task, it’s crucial to understand and follow specific steps to achieve the best possible finish. Below, we present a comprehensive guide on how to apply epoxy coatings effectively.

Surface Preparation

The first step in applying epoxy coatings is thorough surface preparation. Begin by cleaning the surface intended for coating to remove any debris, grease, or dirt that may hinder adhesion. Utilize a degreasing agent for oily surfaces and ensure that it is completely dry before proceeding. Sanding the surface to create a rough texture can significantly increase the binding strength of the epoxy. Don’t skip this step, as it forms the foundation for a successful epoxy coating.

Mixing Instructions

Epoxy coatings typically come in two parts: the resin and the hardener. Proper mixing is essential to activate the chemical reaction that enables the epoxy to cure and harden. Follow the manufacturer’s instructions for the correct mixing ratio, usually found on the product label. Pour the resin and hardener into a clean mixing container and stir thoroughly, ensuring no unmixed components remain. Inadequate mixing can lead to an incomplete cure, compromising the coating’s durability.

Application Techniques

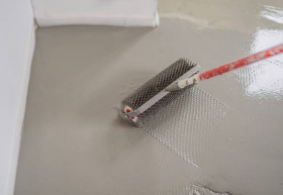

Once mixed, promptly apply the epoxy coating as it will begin to harden. Use a roller or brush to spread the mixture evenly over the prepared surface. Apply in thin, even layers to avoid pooling and ensure smooth coverage. For larger surfaces, a squeegee can be an effective tool for spreading the epoxy uniformly. Work systematically in sections to manage the working time of the mixture, as epoxy tends to cure relatively quickly.

Curing Time

After applying, allow the epoxy coating to cure undisturbed. The curing time varies depending on the product and ambient conditions but generally ranges from 24 to 72 hours. It’s crucial to maintain a stable temperature and humidity level during this period to ensure optimal curing. Avoid foot traffic or placing objects on the coated surface until the epoxy has fully set.

Tips for Best Results

Ensure optimal results by maintaining a dust-free environment during application and curing. Additionally, always adhere to the safety precautions indicated on the product label, including wearing protective gloves and eyewear to prevent skin and eye contact with the epoxy. Avoid common pitfalls such as rushing the preparation phase or neglecting the manufacturer’s instructions, as these steps are vital for a robust and attractive epoxy finish.

Maintenance and Longevity of Epoxy Coatings

The durability and longevity of epoxy coatings are significantly influenced by the maintenance practices adopted post-application. Proper maintenance ensures that these coatings continue to provide robust surface protection and aesthetic appeal for an extended period. Here are some essential tips for maintaining epoxy-coated surfaces.

Regular cleaning is vital to maintain the shine and functionality of epoxy coatings. It is recommended to perform weekly cleaning using a soft broom or a dust mop to remove grit and debris, which can cause surface scratches. Periodic mopping with a mild, non-abrasive cleaner diluted in water will help remove grime without damaging the epoxy finish.

Promptly addressing spills and stains is crucial in preserving the integrity of epoxy surfaces. Wipe up spills immediately using a soft cloth or mop to prevent them from penetrating the coating. For tougher stains, a gentle scrubbing with a soft-bristle brush and a non-abrasive cleaning solution is advisable. Avoid using harsh chemicals like ammonia, bleach, or acidic substances, as these can compromise the coating’s chemical resistance and appearance.

Minor damages such as small chips or scratches should be repaired promptly to prevent further deterioration. Epoxy repair kits are readily available and can be used to fill in chips and cracks, followed by sanding and reapplying a thin layer of epoxy to blend the repair with the rest of the surface. Routine inspections can help identify and address any issues before they escalate, ensuring the coating remains intact and functional.

Well-maintained epoxy surfaces can last for decades, offering both protective and aesthetic benefits. Investing time and effort into regular maintenance not only extends the lifespan of the coating but also enhances its performance, making it a cost-effective solution in the long run.

Customer Experiences and Testimonials

Customers who opt for epoxy coatings from Mithila Paints have consistently given glowing reviews, underlining their satisfaction with both the product’s quality and the service provided. Many clients have shared their real-life experiences, expressing how Mithila Paints met and often exceeded their expectations. From residential garages to large industrial floors, customers have highlighted the durability, aesthetic appeal, and protective qualities of these epoxy coatings.

One client, John A., recounts his experience with Mithila Paints: “After having our garage floor coated, the difference was night and day. The epoxy coating not only transformed the look but also made it incredibly easy to clean. We had some oil spills recently, and they wiped right off without staining the surface.”

Another customer, a small business owner named Karen S., shared her thoughts: “Our bakery kitchen needed a flooring solution that could withstand high foot traffic and spills. The epoxy coatings offered by Mithila Paints have been a game-changer. They are robust and look fantastic! Plus, the team was extremely professional throughout the process.”

Moreover, companies that have chosen Mithila Paints for their large-scale projects express similar levels of contentment. Tom M., a facilities manager at an industrial plant, details: “We had a massive overhaul of our factory floors, and Mithila Paints provided an outstanding epoxy coating solution. It’s remarkable how well it holds up against heavy machinery and constant use.”

These testimonials are testament to Mithila Paints’ commitment to quality and customer satisfaction. Their epoxy coatings are designed to perform exceptionally across various scenarios, whether it’s enhancing the visual appeal of a space or providing the necessary toughness for industrial environments. Users often point out that these coatings not only meet their immediate needs but also offer long-lasting and reliable performance.