Home Paint and Industrial Coatings Manufacturing

The history of home paint and industrial coatings is rich and multifaceted, tracing back thousands of years to when ancient civilizations first experimented with natural pigments. Early humans harnessed minerals, plant extracts, and animal oils to create rudimentary, yet effective, forms of paint used primarily for decorative and protective purposes. For instance, ancient Egyptians employed a variety of natural pigments and binders in their murals, while the Greeks and Romans advanced these techniques by introducing more refined methods and materials.

However, significant breakthroughs in paint and coatings emerged only with the industrial revolution, which catalyzed the development of more advanced formulations. The invention of synthetic pigments and the introduction of oil-based paints in the 18th century marked a pivotal shift from traditional, labor-intensive techniques to more standardized and mass-producible products. By the 19th century, innovations such as the introduction of linseed oil as a binder and the discovery of zinc oxide greatly enhanced the durability and resilience of paints, aligning them more closely with industrial requirements.

The 20th century witnessed an unprecedented surge in technological advancements within the realm of home paint and industrial coatings. The onset of World War II necessitated the rapid development of specialized coatings, leading to the creation of high-performance, corrosion-resistant, and quick-drying formulations. These innovations were not solely confined to military applications; they also found extensive use in commercial and residential settings, thereby broadening the spectrum of paint and coatings available to consumers.

Meanwhile, the latter half of the 20th century saw a growing environmental consciousness, prompting the paint and coatings industry to pivot towards eco-friendly alternatives. The reduction of volatile organic compounds (VOCs) and the development of water-based paints signaled a shift towards sustainable manufacturing practices, driven by both regulatory changes and consumer preferences.

In contemporary times, advancements in materials science and nanotechnology have opened new frontiers in paint and coatings. Modern formulations boast improved aesthetics, enhanced durability, and greater functional properties such as anti-microbial and self-cleaning capabilities. These innovations, coupled with evolving application methods, continue to shape the landscape of home paint and industrial coatings, blurring the lines between form and function.

Types of Home Paints and Their Applications

The home paint market offers a diverse array of options designed to cater to different needs, preferences, and functionalities. Understanding the varieties available can significantly enhance decision-making for optimal outcomes. Broadly, home paints are classified into water-based (latex), oil-based, and specialty paints, each possessing unique characteristics, benefits, and suitable applications.

Water-based, or latex paints, are incredibly popular due to their low odor, quick drying times, and ease of clean-up with water. These paints are known for their environmental friendliness and lower levels of volatile organic compounds (VOCs), making them a favorable choice for interior spaces. Latex paints are flexible and less likely to crack over time, making them ideal for use on walls and ceilings. Furthermore, advances in this category have produced options with greater durability and washability.

Oil-based paints, while less commonly used today, offer certain advantages that can be suitable for specific scenarios. These paints provide a rich, smooth finish and superior adhesion, making them perfect for high-traffic areas, trim work, and cabinetry. Their hard, durable surface is resistant to wear and tear, though they require longer drying times and cleanup involving solvents. Historically favored for their longevity, oil-based paints are now seeing reduced usage due to higher VOC content and environmental concerns.

In addition to these conventional types, specialty paints such as eco-friendly and antimicrobial options are gaining traction. Eco-friendly paints prioritize sustainability, boasting low or zero VOC levels, and often include biodegradable elements. These are ideal for environmentally conscious consumers. Antimicrobial paints, on the other hand, contain additives that inhibit the growth of mold, mildew, and bacteria. They are excellent choices for kitchens, bathrooms, or healthcare facilities where hygiene is paramount.

The importance of color theory and finish types in interior design cannot be overstated. Colors significantly influence mood and perception, hence, understanding their psychological impacts can guide effective selections. Finishes, ranging from matte to gloss, determine the texture and reflectivity of the paint. Matte finishes, with their non-reflective properties, are perfect for hiding imperfections and creating a serene ambiance. In contrast, gloss finishes provide a striking, reflective surface suitable for highlighting architectural features. Combining the right color and finish can dramatically transform a space, aligning with consumers’ aesthetic and functional preferences.

Manufacturing Process of Home Paints

The manufacturing process of home paints is a meticulously orchestrated sequence of steps designed to deliver high-quality and consistent products. The process begins with the procurement of raw materials, which include pigments, binders, solvents, and additives. High-quality raw materials ensure the durability, adherence, and color vibrancy of the final paint product.

The next phase is formulation, where these raw materials are accurately measured and combined according to specific recipes. This formulation step is critical, as it determines the paint’s performance characteristics such as drying time, finish, and coverage. Modern technology plays a crucial role here, with advanced software and automated systems ensuring precision and consistency.

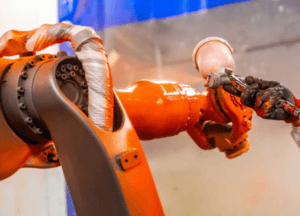

Following formulation is the mixing stage. Industrial mixers and dispersers are utilized to blend the ingredients thoroughly. This creates a uniform consistency and smooth texture. The milling process, often involving bead mills or ball mills, further refines the mixture, breaking down pigment particles and achieving the desired fineness. The use of automation in mixing and milling not only enhances efficiency but also ensures that the paint consistently meets quality standards.

Quality control is an integral aspect of the manufacturing process. Samples are taken at various stages to conduct tests on properties such as viscosity, gloss, drying time, and color accuracy. These tests ensure that each batch adheres to the stringent specifications necessary for high-performance home paint. Advanced analytical instruments and adherence to standardized protocols underscore the importance of maintaining product integrity.

Once the paint passes quality control, it moves to the packaging stage. Automated filling lines efficiently handle this task, reducing human error and increasing throughput. The paints are packed in various sizes suitable for different consumer needs and labeled according to regulatory guidelines.

Environmental considerations are paramount in modern paint manufacturing. Efforts to reduce volatile organic compound (VOC) emissions are essential. Manufacturers adopt eco-friendly formulations and processes to align with regulatory requirements and environmental standards. This includes developing low-VOC and zero-VOC paints, employing sustainable raw materials, and optimizing production techniques to minimize environmental impact.

In essence, the manufacturing process of home paints is a highly sophisticated blend of precision, automation, and stringent quality controls, all while adhering to environmental regulations to produce a superior product for the consumer market.

Industrial Coatings: Purpose and Types

Industrial coatings play a pivotal role in the protection and enhancement of various industrial assets, providing a critical line of defense against environmental and operational challenges. Unlike home paints, which primarily focus on aesthetic appeal and basic surface protection, industrial coatings are meticulously formulated to withstand intense conditions and extend the lifespan of machinery, infrastructure, and other essential equipment.

One of the primary functions of industrial coatings is to provide corrosion resistance. Corrosion, an omnipresent threat in industrial environments, can lead to equipment failure, safety hazards, and substantial financial losses. Epoxies, commonly used in industrial scenarios, are renowned for their excellent adhesion and chemical resistance properties, making them ideal for protecting metal surfaces from corrosive agents.

Polyurethanes, another category of industrial coatings, offer a robust combination of flexibility and durability. These coatings are highly resistant to abrasion and impact, which means they are well-suited for areas experiencing significant wear and tear. They also provide excellent UV resistance, making them a preferred choice for outdoor applications where exposure to sunlight could degrade other types of coatings.

Fluoropolymers are specialized industrial coatings known for their exceptional non-stick properties and high resistance to chemicals and heat. These coatings are used in a range of high-performance applications, from non-stick surfaces in cookware to protective layers in aerospace components. Their inherent stability under extreme temperatures and corrosive environments makes them indispensable in settings where other coatings might fail.

In summary, the intricate formulations and specialized functionalities of industrial coatings are vital for shielding and enhancing industrial assets. Whether through providing corrosion resistance with epoxies, durability with polyurethanes, or advanced chemical and heat resistance with fluoropolymers, industrial coatings ensure that machinery and infrastructure maintain their performance and integrity across various challenging environments.

Technological Advancements in Coatings

Recent years have witnessed significant technological advancements in the field of home and industrial coatings. A noteworthy innovation is the development of smart coatings, which exhibit properties that can change in response to environmental stimuli. These coatings can be designed to respond to temperature variations, light exposure, or even physical stress, allowing for dynamic performance enhancements. For instance, smart coatings that incorporate phase change materials can regulate temperature by absorbing and releasing heat, leading to more energy-efficient buildings.

Another pivotal advancement is the creation of environmentally friendly formulations. Traditional coatings often contain volatile organic compounds (VOCs), which can have detrimental effects on both the environment and human health. However, modern formulations prioritize sustainability by reducing or eliminating VOC content. Water-based coatings and bio-based polymers are prime examples, offering reduced environmental impact while maintaining high performance levels. These innovations not only contribute to a safer production process but also enhance indoor air quality.

Nanotechnology has also revolutionized the coatings industry, offering products with unprecedented capabilities. Nano-coatings are engineered at the molecular level to provide superior protection and functionality. For example, nanoparticles can be added to coatings to increase scratch resistance, UV protection, and even self-cleaning properties. A notable application is in industrial settings where nano-coatings enhance the durability and longevity of equipment, reducing maintenance costs and downtime.

A case in point is the implementation of nanotechnology in the automotive industry. Manufacturers are now using nano-coatings to create hydrophobic surfaces that repel water, oil, and dirt, thereby extending the lifespan of vehicle exteriors and reducing the need for frequent cleanings. These advancements not only improve performance but also offer cost efficiency in the long run.

The integration of smart coatings, environmentally friendly formulations, and nanotechnology has significantly enhanced the quality and sustainability of both home and industrial coatings. These innovations represent a paradigm shift towards more efficient and eco-friendly solutions, setting new benchmarks for the industry.

The Role of Quality Control in Paint and Coatings Manufacturing

In the intricate realm of paint and coatings manufacturing, quality control plays a pivotal role in ensuring product excellence. Integral to this process are rigorous standards and meticulous testing procedures, designed to uphold consistency and dependability. Adherence to established benchmarks such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) is paramount, as these standards dictate the essential parameters for quality and reliability. By conforming to these protocols, manufacturers can confidently deliver products that meet both regulatory requirements and customer expectations.

Various sophisticated tools and techniques are employed to maintain high quality across the production lifecycle. Spectrophotometry, for instance, is an indispensable technique in confirming color accuracy. This method measures the intensity of light as a function of its color to ensure that the hues produced match the specified standards consistently. Utilizing this technology helps manufacturers maintain uniformity in the appearance of their products, which is a critical factor for consumer satisfaction and brand integrity.

Furthermore, mechanical tests are conducted to evaluate the durability and adhesion properties of paints and coatings. These tests are essential to ascertain the product’s performance under diverse environmental conditions. Adhesion tests, for example, determine how well the coating sticks to various substrates, which directly impacts its longevity and effectiveness. Durability tests, on the other hand, simulate wear and tear scenarios to predict how long the coating will last before it begins to deteriorate or lose its protective qualities.

Quality assurance in paint and coatings manufacturing is a multifaceted endeavor that encompasses various testing methodologies and adherence to stringent standards. It is through these rigorous quality control practices that manufacturers can produce reliable, high-performance products, ensuring they meet the demands of both industrial applications and consumer needs. By investing in advanced quality control technologies and upholding comprehensive testing protocols, the industry continues to innovate and enhance the reliability and aesthetic appeal of paints and coatings.

Market Trends and Consumer Preferences

The home paint and industrial coatings market continue to evolve, driven by shifting consumer preferences and market dynamics. A significant trend is the increased demand for eco-friendly products. As environmental concerns grow, consumers are opting for paints and coatings that are low in volatile organic compounds (VOCs) and other harmful chemicals. According to recent market research, eco-friendly paints are expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028, reflecting this green shift among consumers.

Durability is another crucial factor influencing consumer preferences. Consumers are not only looking for paints and coatings that add aesthetic value but also those that enhance the longevity of surfaces. In industrial applications, durable coatings that offer resistance to chemicals, abrasion, and weather conditions are in high demand, ensuring the longevity and performance of industrial equipment and structures.

Aesthetics continue to play a vital role in consumer decisions within the home paint sector. The increasing number of color options, textures, and finishes cater to diverse consumer preferences, enabling homeowners to personalize their living spaces. Technological advancements, such as the development of smart coatings that change color or reflectivity in response to environmental conditions, further enhance the appeal and functionality of paint products.

Furthermore, economic conditions significantly impact the home paint and industrial coatings industries. Periods of economic growth usually see increased consumer spending on home renovations and construction projects, thereby boosting demand for paints and coatings. Conversely, economic downturns may result in reduced spending but can also spur innovations as manufacturers look for cost-effective solutions and new ways to entice budget-conscious consumers.

Regulatory changes also shape market trends. Increasingly stringent environmental regulations propel manufacturers to innovate and produce safer, more sustainable products. In response to these regulations, several companies are investing in research and development to create compliant, high-performance products.

In conclusion, the home paint and industrial coatings market is subject to a myriad of influences, including the growing demand for sustainable products, the importance of durability and aesthetic appeal, economic conditions, technological advancements, and regulatory requirements. These factors collectively drive market trends and shape consumer preferences, ensuring continuous evolution and innovation within the industry.

Future Outlook and Challenges

The future of home paint and industrial coatings manufacturing is poised at a crossroads marked by both significant opportunities and formidable challenges. The primary concern for manufacturers remains the volatility in the availability and cost of raw materials. As global supply chains grapple with disruptions, there is a growing emphasis on developing more resilient and localized sourcing strategies to mitigate these risks. Manufacturers are likely to invest heavily in alternative and synthetic raw materials that can offer both cost efficiency and a reduced environmental footprint.

Environmental regulations are becoming increasingly stringent, pushing the industry towards adopting greener practices. The push for sustainability has never been more pronounced, and manufacturers are anticipated to focus on producing eco-friendly paints and coatings. This includes formulations with lower volatile organic compounds (VOCs), reducing toxic emissions, and enhancing recyclability. Adhering to these regulations not only ensures compliance but also caters to the eco-conscious consumer, driving a positive market perception.

Market demands are continually evolving, with a marked shift towards customizable and multifunctional coatings. Consumers and industries now seek products that are not only aesthetically pleasing but also offer added functionalities such as anti-microbial properties, enhanced durability, and resistance to extreme conditions. This trend necessitates continuous innovation and the adoption of advanced research and development methodologies.

One of the most transformative influences on the home paint and industrial coatings sector over the next decade will be the incorporation of automation and digital technologies. The adoption of Industry 4.0 principles, including artificial intelligence, machine learning, and the Internet of Things (IoT), promises to revolutionize manufacturing processes. These technologies can optimize production efficiency, ensure higher quality control, and enable predictive maintenance, thereby reducing downtime and operational costs.

In conclusion, while the home paint and industrial coatings industry faces significant challenges, it also presents vast opportunities for growth and innovation. By embracing sustainable practices, investing in new materials, and leveraging the power of advanced technologies, manufacturers can navigate the complexities of the future landscape, ensuring a robust and resilient industry.