Introduction to Heat-Resistant Industrial Paints

Heat-resistant industrial paints play a critical role in various industrial applications, providing essential protection and durability to surfaces exposed to high temperatures. These specialized coatings are designed to withstand extreme heat without compromising their integrity, appearance, or protective features. This is particularly important in industries such as aerospace, automotive, manufacturing, and petrochemical, where equipment and structures often experience significant thermal stress.

The formulation of heat-resistant paints typically includes advanced resins and additives that enhance their thermal stability. One of the defining properties of these coatings is their ability to maintain adhesion and color retention even when subjected to temperatures that would damage standard paints. This capability extends the lifespan of painted surfaces and reduces the need for frequent maintenance or repainting, making heat-resistant paints not only a practical choice but also an economically viable one.

In addition to temperature resistance, these paints are often designed to possess other beneficial characteristics. For instance, many heat-resistant industrial paints also offer excellent chemical resistance, which protects surfaces from corrosive substances frequently encountered in industrial settings. Furthermore, some formulations provide UV resistance, which protects against degradation caused by prolonged sun exposure, together reinforcing the protective qualities of the coating.

Heat-resistant industrial paints can be applied to a variety of substrates, including metals, plastics, and ceramics, making them versatile for numerous applications. Additionally, they come in various colors and finishes, allowing for customization according to aesthetic or operational requirements. Overall, the strategic use of heat-resistant paints is integral to enhancing the performance and longevity of industrial equipment and structures exposed to high-temperature environments.

Importance of Heat-Resistant Coatings

Heat-resistant coatings play a vital role in multiple industries, including manufacturing, automotive, and aerospace. These sectors often operate in environments subject to elevated temperatures that can compromise the structural integrity and performance of materials. The adverse effects of extreme heat on equipment and components can lead to diminished efficiency, increased maintenance costs, and even catastrophic failures in critical applications.

In manufacturing processes, machinery and tools frequently experience high temperatures due to friction and extended operational hours. Applying heat-resistant coatings not only enhances the longevity of equipment but also maintains optimal performance levels. This is essential for ensuring production efficiency and minimizing downtime, which can be costly for businesses in competitive markets.

The automotive industry also significantly benefits from heat-resistant coatings, especially in components that are subjected to high temperatures, such as engine parts and exhaust systems. These coatings help in resisting thermal degradation, preventing deterioration that could lead to malfunctions and costly repairs. Furthermore, the application of such coatings can enhance safety by reducing the risk of fires and explosions associated with overheating components.

Aerospace applications highlight the necessity of heat-resistant coatings due to the extreme thermal conditions experienced during high-speed flight and re-entry. Coating materials must endure not only high temperatures but also the corrosive effects of fuel and other airborne substances. By utilizing advanced heat-resistant coatings, companies in the aerospace sector can ensure that their vehicles maintain performance and safety standards throughout their operational lifespan.

Mithila Paints understands these industry-specific challenges and offers effective solutions that address the vulnerabilities associated with high heat exposure. Our heat-resistant coatings are engineered to withstand extreme temperatures while providing exceptional protection and durability, enabling industries to operate efficiently and safely.

Applications of Mithila’s Heat-Resistant Paints

Mithila’s heat-resistant paints have become an essential solution for a variety of industries where high-temperature exposure is a common challenge. These specialized coatings are engineered to withstand extreme conditions, making them indispensable in sectors such as automotive, aerospace, manufacturing, and energy. One prominent application can be found in exhaust systems, where the temperatures can soar due to the high-performance nature of modern engines. Mithila’s heat-resistant paint provides a durable barrier that prevents rust and corrosion, while also maintaining aesthetic appeal even under harsh conditions.

In addition to automotive applications, these paints are widely used in furnace and boiler operations. Industrial furnaces reach temperatures that can exceed 1000 degrees Celsius, leading to degradation of unprotected surfaces. By applying Mithila’s heat-resistant coatings, operators can prolong the lifespan of these crucial components, thereby reducing maintenance costs and downtime. The same principle applies to various equipment utilized in material processing and production, such as kilns and ovens, where thermal insulation is critical to operational efficiency.

Pipelines and storage tanks also benefit significantly from Mithila’s heat-resistant paints. In the oil and gas industry, for instance, temperatures can fluctuate dramatically, making it essential to utilize coatings that can manage these variations while ensuring safety. Mithila’s products not only protect against heat but also provide resistance to chemicals and UV radiation, thereby extending the life of these valuable assets. Furthermore, the coatings’ versatility allows for application on diverse materials, including metal, concrete, and plastic, making them suitable for a broad range of situations.

Overall, the applications of Mithila’s heat-resistant paints span multiple sectors, showcasing their critical role in enhancing durability and performance under extreme thermal conditions.

Key Features of Mithila Heat-Resistant Paints

Mithila Heat-Resistant Paints present a comprehensive solution for industries requiring robust protective coatings capable of withstanding extreme temperatures. One of the standout features of these paints is their impressive temperature tolerance, capable of resisting temperatures up to 650 degrees Fahrenheit (343 degrees Celsius) without compromising integrity. This exceptional thermal stability makes them ideal for use in environments such as industrial facilities, power plants, and automotive applications where exposure to high heat is frequent.

Furthermore, Mithila’s formulation includes advanced chemical resistance properties, ensuring that the paint maintains its performance even in the presence of corrosive substances. This feature is crucial for applications where chemicals, oils, or solvents are prevalent, helping to prolong the life of the coated surface and reduce maintenance expenditures. The ability of the paint to resist wear and corrosion is enhanced by the state-of-the-art polymers utilized in its formulation, promoting superior adhesion and flexibility under heat stress.

An additional advantage of Mithila Heat-Resistant Paints is their remarkable durability. These paints are designed to withstand physical wear, including scratching and abrasion, which is particularly beneficial in high-traffic areas or heavy machinery applications. Their resilience minimizes the frequency of reapplications, thereby offering a cost-effective solution over time.

Ease of application is another significant feature of Mithila’s heat-resistant paints. With formulations that allow for smooth application processes, these paints can be easily rolled or sprayed, saving time during installation. Innovations in the formulation also mean that the paints dry quickly, enabling faster turnaround times for projects. These attributes collectively position Mithila Heat-Resistant Paints as a premier choice in the competitive landscape of industrial coatings.

Benefits of Choosing Mithila Paints

Mithila Paints offers a range of advantages that elevate it above other brands in the industrial paints market. One of the standout benefits is the long-lasting performance of its heat-resistant products. These paints are specially formulated to withstand extreme temperatures without compromising their physical properties. The durability ensures that surfaces remain protected from thermal stress and environmental factors, thus reducing the need for frequent reapplications and maintenance.

Another notable advantage of Mithila Paints is its superior coverage. The paint formulations are designed to provide excellent hiding power, allowing users to achieve a smooth, uniform finish even with minimal coats. This efficiency not only saves time but also optimizes material usage, offering economic benefits to businesses engaged in large-scale projects. The high-quality pigments used in the creation of Mithila Paints contribute to vivid, long-lasting colors that enhance the aesthetic appeal of industrial applications.

In today’s eco-conscious world, environmental safety has become a critical factor in product selection. Mithila Paints prioritizes sustainability in its manufacturing processes, ensuring that the products are compliant with safety regulations and free from harmful solvents. Customers can feel confident knowing they are using paints that pose minimal risk to their health and the environment, enhancing workplace safety and reducing the ecological footprint.

Moreover, Mithila Paints is committed to exceptional customer service. The brand prides itself on being responsive and helpful, providing customers with the guidance they need to select the right products for their specific requirements. Testimonials from satisfied clients highlight the brand’s reliability and consistent delivery, reinforcing its reputation in the industrial paint sector.

Overall, the combination of long-lasting performance, superior coverage, environmental safety, and outstanding customer service makes Mithila Paints a compelling choice for anyone in need of heat-resistant industrial paints.

Application Techniques for Optimal Results

Applying heat-resistant industrial paints effectively is essential for ensuring durability and performance, particularly in high-temperature environments. To achieve optimal results, meticulous attention to surface preparation, application methods, and drying or curing times is necessary.

First, surface preparation is a critical step that cannot be overlooked. Start by cleaning the surface to be painted. Any contaminants such as grease, oil, dust, or previous coatings should be removed thoroughly, as they can impede adhesion. Depending on the surface material, a sandblasting or pressure washing technique may be useful. After cleaning, the surface should be lightly sanded to create a texture that promotes adhesion. For rusted or heavily corroded surfaces, a rust-inhibiting primer may be needed to enhance long-term performance.

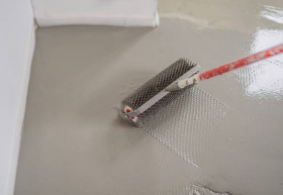

Once the surface is prepared, choosing the correct application method is paramount. Heat-resistant paints can be applied using different techniques, including spraying, brushing, or rolling. Spraying is often the preferred method for larger areas or complex shapes, as it provides an even coat and reduces the risk of brush marks. For smaller areas, brushing may be more appropriate, ensuring that each stroke covers the surface uniformly. It is important to follow the manufacturer’s guidelines to choose the optimal nozzle size and pressure settings when using a spray gun, as these parameters can greatly influence the finish quality.

Finally, attention must also be paid to drying and curing times, which will vary depending on the specific product used. After application, allow the paint to dry thoroughly before subjecting it to heat or stress. The curing process is typically essential for the paint’s chemical structure to strengthen, enhancing its heat-resistance capabilities. Always consult the technical data sheet provided by Mithila Paints for exact specifications, as this will help ensure the success of your application, thereby maximizing the paint’s performance in demanding environments.

Compliance and Safety Standards

In the industrial coatings sector, compliance with established regulations and safety standards is paramount. Mithila Paints recognizes this necessity and diligently adheres to a comprehensive suite of guidelines designed to ensure the safety and reliability of its heat-resistant industrial paints. These standards not only guarantee product efficacy but also enhance overall environmental protection and customer safety.

One significant standard that applies to industrial paints is the ISO 9001 certification, which delineates the criteria for a quality management system. This certification mandates rigorous testing and quality assurance measures during the manufacturing process. By meeting ISO 9001 standards, Mithila Paints ensures that its products consistently provide high performance and reliability, a critical factor for industries relying on heat-resistant paints for high-temperature applications.

Furthermore, compliance with environmental regulations such as the Environmental Protection Agency (EPA) guidelines is integral to Mithila Paints’ manufacturing processes. These regulations aim to minimize harmful emissions and ensure that all industrial paints are produced with a focus on sustainability. This not only furthers environmental protection but also allows customers to make more informed choices about the products they utilize in their operations. Additionally, the Occupational Safety and Health Administration (OSHA) standards are abided by, ensuring that the workplace environment remains safe for employees. This adherence safeguards both the personnel involved in manufacturing and the end-users of these paints.

Through these committed compliance measures, Mithila Paints delivers not only heat-resistant industrial paints that meet the functional demands of various applications but also fosters a culture of safety and environmental responsibility. The resulting benefits to customers include reliable, high-performance products that align with best practices and industry standards, further solidifying their trust in Mithila Paints’ commitment to quality and safety.

Customer Support and Resources

Mithila Paints recognizes the vital role that customer support plays in ensuring the successful application and maintenance of its heat-resistant industrial paints. To facilitate an informed and satisfactory user experience, Mithila Paints provides a comprehensive range of resources tailored to meet individual client needs. This includes detailed product guides that explore the specifications, application techniques, and performance characteristics of their heat-resistant paints.

In addition to product guides, Mithila Paints offers technical support designed to assist customers in overcoming specific challenges encountered during the application process. Customers can reach out to a dedicated support team equipped with the know-how to provide precise solutions to questions regarding curing times, surface preparation, and long-term durability of the paints. This expertise is critical for industries that require the utmost reliability under demanding conditions.

The company’s commitment to customer success extends to consulting services as well. Mithila Paints understands that every industrial operation may have unique requirements. Therefore, personalized consultations are available for customers seeking advice on selecting the most suitable heat-resistant paint for their specific application. This consultative approach ensures that users not only choose the right product but also understand how to maximize its effectiveness for optimal results.

Furthermore, Mithila Paints maintains an online resource hub that offers instructional videos, case studies, and FAQs, making it easier for users to access vital information. These resources act as an additional layer of support, helping clients stay informed about industry best practices related to heat-resistant paints.

By offering extensive support and resources, Mithila Paints aims to empower customers in their choices and applications, leading to enhanced satisfaction and successful outcomes in their projects.

Conclusion and Future Trends

In conclusion, heat-resistant industrial paints play a crucial role in protecting surfaces from high temperatures and corrosive environments. By understanding the key characteristics and applications of these specialized coatings, industries can better select the appropriate products for their operational needs. The benefits of heat-resistant paints not only include enhanced durability and protection but also contribute to improved aesthetic appeal and overall safety in various applications.

As we look ahead to future trends in the realm of heat-resistant coatings, innovation remains at the forefront. Advances in technology are paving the way for the development of new formulations that offer even greater resistance to heat, chemicals, and physical wear. Trends indicate a growing interest in eco-friendly and sustainable coatings, which are formulated to minimize environmental impact while delivering exceptional performance. Furthermore, advancements in nanotechnology may lead to the emergence of heat-resistant paints with unparalleled properties, providing better coverage and enhanced application techniques.

Mithila Paints is dedicated to responding to these evolving trends and investing in research and development for heat-resistant industrial paints. By focusing on continuous improvement and customer needs, Mithila Paints aims to enhance its product offerings to meet the demands of various industries. As the market for heat-resistant coatings expands, it is essential for manufacturers to keep innovating, ensuring the products provided not only meet today’s standards but also anticipate the needs of the future.