Introduction to High-Performance Paint

High-performance paint represents an advanced classification of coatings designed to provide superior characteristics compared to traditional paint options. Characterized by enhanced durability, exceptional adhesion, and resistance to environmental factors, high-performance paint is ideal for various applications that demand longevity and aesthetic excellence. Unlike standard paints, which may fade or deteriorate under harsh conditions, high-performance variants maintain their integrity and visual appeal over extended periods.

One of the defining features of high-performance paint is its formulation, which typically includes advanced resins and additives. These components work synergistically to improve the paint’s resistance to chemicals, UV rays, moisture, and abrasion. This robust formulation makes high-performance paint particularly suitable for industries such as automotive, aerospace, and construction, where exposure to extreme elements is commonplace. For instance, in the automotive sector, high-performance paint not only provides a visually striking finish but also protects vehicles from wear and corrosion, thereby extending their lifespan.

The significance of investing in high-performance paint cannot be overstated, especially for projects where aesthetics and protection are paramount. In the aerospace industry, the weight and surface finish of the paint can directly influence performance and efficiency, leading to the use of specialized coatings that fit these stringent requirements. Similarly, in construction, high-performance solutions offer both protection for buildings and visual enhancements, ensuring that structures remain attractive while withstanding the test of time and environmental stresses.

Ultimately, high-performance paint serves as a crucial investment, providing benefits that outweigh the initial costs. Its unique properties not only elevate the quality of finishes but also contribute to the sustainability of structures and products, making it an essential consideration for industry professionals seeking lasting solutions. The integration of mithila paints into this category can further enhance the creative expression within various applications, bringing forth a fusion of durability and artistic flair.

Benefits of High-Performance Paint

High-performance paint offers a myriad of advantages that make it an essential choice for both residential and commercial applications. One of the primary benefits is its enhanced durability. Unlike traditional paints that may chip, fade, or wear out quickly, high-performance options are formulated to withstand harsh environmental conditions. This resilience ensures that surfaces remain intact and visually appealing for extended periods, minimizing the need for frequent repainting.

Another significant advantage is superior weather resistance. High-performance paint is engineered to endure extreme temperatures, humidity fluctuations, and ultraviolet (UV) exposure. This quality not only protects the underlying surface but also preserves the vibrancy of colors over time. For example, mithila paints, renowned for their intricate designs and cultural significance, benefit from high-performance formulations that prevent degradation under natural elements, thereby maintaining their artistic integrity.

Furthermore, high-performance paints provide improved coverage compared to standard products. This characteristic allows for fewer coats to achieve an even finish, reducing both labor time and material costs. This efficiency can lead to cost savings over time, making high-performance options a financially sound choice for various projects.

Aesthetic versatility is yet another key benefit of these advanced paints. Available in a wide range of colors and finishes, high-performance paint can cater to various design preferences—be it a modern, sleek look or a classic, intricate style. This versatility allows home and business owners to express their personal aesthetic while also ensuring a protective layer for surfaces.

In conclusion, the unique advantages of high-performance paint, including enhanced durability, superior weather resistance, improved coverage, and aesthetic diversity, make it a prudent investment for anyone seeking to elevate the quality and appearance of their spaces. These benefits contribute significantly to long-term cost efficiency and reduced maintenance efforts.

Types of High-Performance Paint

High-performance paints come in various formulations, each designed for specific applications and performance characteristics. The most common types include epoxy, polyurethane, and acrylic paints, among others. Understanding the unique properties and best uses of these types enables consumers, contractors, and businesses to make informed decisions for their projects.

Epoxy Paint: Epoxy paint is well-known for its superior adhesion and resistance to chemicals, making it ideal for surfaces that experience heavy wear and tear. Often utilized in industrial settings, epoxy is frequently employed on floors where spills or abrasion are likely. Its durability ensures a lasting finish that can withstand extreme conditions, although its application is most suited for environments that require robust protection. The curing process may require more attention, as proper application is essential for optimal performance.

Polyurethane Paint: Polyurethane paint is another high-performance option, celebrated for its glossy finish and resistance to UV radiation. This makes it an excellent choice for exterior applications such as woodwork, automotive finishes, and even metal surfaces. Polyurethane can be applied in two forms: one-component and two-component systems. The latter offers enhanced durability and higher protective qualities, thereby justifying its widespread adoption for both residential and commercial projects.

Acrylic Paint: Acrylic paint, known for its versatility and quick-drying properties, is widely used in various sectors, including art, crafts, and construction. This type of high-performance paint adheres well to numerous surfaces and is less toxic compared to other alternatives. It provides excellent color retention and flexibility, making it suitable for exterior walls and surfaces exposed to the elements. Acrylics can offer a cost-effective solution without sacrificing performance, especially when long-lasting, vibrant finishes are required.

Overall, the selection of the appropriate high-performance paint—be it epoxy, polyurethane, or acrylic—depends on the specific requirements of the project, including environmental factors and the desired aesthetic. Each of these types brings unique advantages, making them suitable for a range of applications across multiple industries.

Key Applications of High-Performance Paint

The scope of high-performance paint extends across numerous industries, reflecting its versatility and durability. One significant sector is automotive, where high-performance paint is used not only for aesthetic enhancement but also for protection against corrosion and environmental damage. Various car manufacturers, for instance, apply advanced coatings that withstand harsh weather conditions, ensuring long-lasting vibrancy and safeguarding the vehicle’s metallic surfaces.

In industrial manufacturing, high-performance coatings play a crucial role in protecting machinery and equipment from wear and tear. These paints serve as a barrier against rust, chemical exposure, and physical abrasion. Facilities that produce heavy machinery often choose specialized mithila paints formulated to meet stringent performance standards, thus prolonging the lifespan of their equipment and minimizing maintenance costs.

The marine industry also significantly benefits from high-performance paints. Boats and ships are exposed to seawater, which can lead to severe corrosion if not adequately protected. Marine-grade paints, such as antifouling coatings, are designed to prevent the growth of barnacles and algae, ensuring both aesthetic appeal and functional efficiency. Various case studies highlight the effectiveness of these paints, where vessels have shown improved performance and extended service intervals due to their use.

Lastly, high-performance paint finds applications in the home improvement sector. Homeowners increasingly opt for these specialized coatings to enhance the durability of surfaces, especially in high-traffic areas. For example, interior and exterior walls treated with high-performance paint exhibit greater resistance to stains and fading, maintaining their visual appeal over time. Such paints can also incorporate elements like mildew resistance, ideal for humid environments.

Through these applications in various sectors, high-performance paint demonstrates remarkable adaptability, showcasing its essential role across diverse environments and industries.

Surface Preparation for High-Performance Painting

Proper surface preparation is a crucial element in ensuring the success of high-performance painting, especially when utilizing specialty coatings such as mithila paints. The aesthetics and durability of the finish are directly influenced by the condition of the surface being treated. Consequently, meticulous attention to detail during the preparation phase can prevent complications later on.

The initial step in the preparation process involves thorough cleaning of the surface. This step aims to remove any dirt, dust, grease, or old paint that may impede the new coating’s ability to adhere effectively. Using appropriate cleaning agents or solvents is crucial; for instance, degreasers can be used for surfaces that are particularly oily. After cleaning, allowing the surface to dry completely is essential before proceeding to the next phase.

Once the surface is cleaned, sanding becomes necessary to ensure that the substrate is smooth and ready for priming. Sanding not only improves the texture of the surface but also supports better adhesion of the high-performance paint, including mithila paints. For large areas, power sanders can expedite the process, while hand sanding may be suitable for intricate details. Following sanding, it is critical to remove any dust generated during this step, often accomplished through vacuuming or wiping down with a damp cloth.

After these preparatory steps, applying a primer is recommended, especially for porous surfaces or those previously coated with non-compatible paints. Priming provides a uniform base for the high-performance paint, enhancing both adhesion and finished appearance. Utilizing a primer specifically designed to work with the selected paint can significantly enhance the longevity and viability of the coating. Neglecting proper surface preparation can lead to adhesion issues, which may ultimately compromise the paint’s ongoing durability and performance.

Application Techniques for High-Performance Paint

The successful application of high-performance paint is crucial in achieving both durability and aesthetic appeal. Various application methods exist, each with its own set of advantages and best practices. The primary techniques for applying mithila paints include brushing, rolling, and spraying, each suited for different surfaces and project requirements.

Brushing is often favored for precise application, especially on smaller areas or detailed surfaces. Its advantage lies in the control it provides, allowing the painter to manage the amount of paint applied and to reach into corners and edges effectively. However, to achieve the best finish, it is essential to use the appropriate brush type, typically one made from synthetic materials when working with water-based mithila paints, which helps prevent the bristles from absorbing moisture and reduces the risk of leaving brush marks.

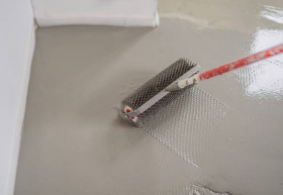

The rolling method is ideal for larger, flat surfaces, as it enables quicker coverage. Rolls made of high-quality material are crucial here; they can hold considerable amounts of paint while minimizing texture and creating an even layer. When using this technique, applying even pressure and maintaining a consistent speed will help ensure a smooth finish. It may also be beneficial to use a brush for edges and touch-ups post-application.

Spraying is a technique often chosen for its efficiency and smooth finish, particularly on expansive surfaces like walls or exteriors. Airless sprayers or HVLP (High Volume Low Pressure) sprayers can create a fine mist, reducing the appearance of roller or brush marks. However, achieving the desired finish requires careful control over the spray pattern and distance from the surface being painted. Adequate preparation and ventilation are critical when using this method to safeguard against overspray and ensure a professional-quality coat.

Regardless of the chosen application technique, following manufacturer guidelines for specific mithila paints is essential. These instructions provide valuable insights into surface preparation, drying times, and environmental conditions necessary to achieve optimal results. Proper technique combined with adherence to guidelines ensures longevity and visual appeal of the final painted surface.

Maintenance and Longevity of High-Performance Paint

Maintaining surfaces coated with high-performance paint is essential to ensuring their durability and aesthetic appeal over time. Regular cleaning is one of the most effective strategies for preserving the integrity of mithila paints and similar high-quality coatings. It is recommended to use a mild detergent mixed with water for the initial cleaning process. This routine should be conducted at least once every six months, or more frequently if the surface is exposed to harsh environmental conditions, such as salty air or heavy pollution. Using soft cloths or sponges is advisable to avoid scratching the painted surface.

Environmental conditions can significantly affect the longevity of plays using mithila paints. For instance, areas with high humidity levels can lead to mold and mildew growth, which may deteriorate the paint over time. It is crucial to monitor these conditions and address any moisture issues promptly. Furthermore, surfaces exposed to intense sunlight may experience fading, necessitating the use of UV-protective coatings alongside the initial paint. Ensuring that painted surfaces are well-ventilated is also vital since this helps maintain an equilibrium that minimizes moisture buildup.

Identifying signs that indicate the need for touch-ups or reapplication can help maintain the high-performance qualities of the painted surfaces. Look for discoloration or peeling as key indicators that the protective barrier of the paint has been compromised. Additionally, any bubbling or cracking can signify underlying issues that should be addressed. By watching for these signals, homeowners and property managers can initiate touch-ups before the need for extensive repainting arises. In conclusion, with appropriate maintenance routines and awareness of environmental conditions, the longevity and aesthetics of surfaces painted with high-performance paints can be significantly enhanced, ensuring a lasting visual impact.

Challenges and Considerations

High-performance paints are lauded for their superior durability and aesthetic qualities, but they also come with a set of challenges that users must navigate. One significant hurdle is the application process, which may require specialized techniques and tools to achieve the desired finish. Unlike traditional paints, mithila paints and other high-performance varieties often necessitate meticulous surface preparation, including priming and sanding, to ensure proper adhesion and longevity. This added step can deter those who are accustomed to simpler painting processes.

Another challenge associated with high-performance paints is their longer drying times. While these paints often cure to a tougher finish, patience is required during the drying phase. This extended timeline can disrupt project planning, especially for commercial applications where time efficiency is paramount. It is advisable to check the manufacturer’s guidelines for recommended drying periods and conditions, allowing for appropriate scheduling.

The initial costs of high-performance paints, including mithila paints, tend to be higher than standard options. Although the upfront investment may be daunting, stakeholders should consider the long-term benefits, such as reduced maintenance costs and prolonged paint life. To mitigate the financial burden, it is prudent to conduct a cost-benefit analysis that assesses the expected lifespan and maintenance frequency associated with each product.

Ultimately, selecting the right high-performance paint requires an understanding of these challenges, balancing them with their many benefits. Consider consulting with professionals or paint specialists to ensure that your choice adequately aligns with your specific project needs and conditions. With careful planning and execution, the potential challenges of high-performance paints can be successfully navigated, leading to a durable and visually appealing result.

Future Trends in High-Performance Paint

The future of high-performance paint is set to be influenced by a combination of technological advancements and a growing commitment to sustainability. Innovations in paint technology are paving the way for more durable and aesthetically pleasing finishes. Manufacturers are increasingly investing in research and development to create paints that not only provide long-lasting protection but also enhance the visual appeal of surfaces.

A significant trend is the move towards eco-friendly formulations. In response to growing environmental concerns and regulations, paint manufacturers are formulating products with lower volatile organic compounds (VOCs). This shift is indicative of a larger trend aimed at reducing the environmental impact associated with traditional paint products. Additionally, the incorporation of bio-based materials in paint formulations contributes to sustainability, ensuring that high-performance paints align with modern eco-conscious consumer preferences.

Another area of innovation is the evolution of application processes. New techniques and equipment have been developed to ensure a more efficient application of high-performance paints. Advanced spray technologies, for instance, are being adopted to minimize waste and improve coverage, allowing for a smoother finish while reducing the time and effort required for application. Techniques such as electrostatic spray painting are also gaining traction, providing improved transfer efficiency and reducing overspray.

Experts in the field predict that the combination of smart technology and high-performance coatings will revolutionize how paints are used in various applications. The integration of sensors and smart materials capable of changing properties in response to environmental conditions promises to enhance the functionality of high-performance paints. Such innovations suggest a future where paints do more than add color—they provide added features such as self-cleaning surfaces or UV protection, expanding their application across different sectors.

In conclusion, the landscape of high-performance paint is evolving rapidly, influenced by advancements in technology, a commitment to eco-friendliness, and innovative application methods, all of which will enhance the durability and aesthetics of paint products in the coming years.