Introduction to the Home Paint and Texture Manufacturing in Gujarat

The paint and texture industry in Gujarat plays a pivotal role in the state’s economy, contributing significantly to employment and revenue generation. As one of the fastest-growing sectors within the region, it showcases a dynamic blend of innovation and tradition. The vibrant landscape of home paint manufacturing is characterized by a variety of products offering aesthetic and protective solutions for residential properties, thereby enhancing their visual appeal and durability.

Gujarat’s strategic location, combined with a rich supply of raw materials, has facilitated the growth of numerous paint manufacturing companies. This industry encompasses a wide range of formulations, including water-based, oil-based, and eco-friendly alternatives. As the demand for sustainable products increases, manufacturers are shifting their focus toward environmentally friendly options, such as mithila home paint, which aligns with global green initiatives.

In terms of market size, the paint sector in Gujarat has experienced substantial growth, with estimates showing it accounting for a significant percentage of India’s overall paint consumption. Key players in the market include both established brands and new entrants, fostering healthy competition that drives innovation and quality. Furthermore, Gujarat serves not only as a supplier for the domestic market but also as an exporter, bolstering its reputation on the international stage.

The advent of advanced technology and manufacturing techniques has further propelled the industry forward. Companies are investing in research and development, creating unique textures and finishes that cater to diverse consumer preferences. This ongoing evolution underscores the significance of the paint and texture industry in Gujarat, as it adapts to changing market demands while remaining committed to excellence in product quality. The future looks promising as the region continues to solidify its position as a major hub for home paint production, including the ever-popular mithila home paint.

Historical Background and Development

The history of paint and texture manufacturing in Gujarat can be traced back to the early 20th century, when the region began emerging as a significant hub for various industries. The establishment of the first major paint manufacturing companies laid the groundwork for what would become a vibrant sector. Initially, the focus was primarily on basic paints, but as the market evolved, so did the demand for more specialized products.

Throughout the decades, technological advancements played a crucial role in the evolution of the industry. In the 1950s and 1960s, the introduction of synthetic resins revolutionized the formulation of paints. This shift not only enhanced the durability and aesthetic appeal of products but also made painting with mithila home paint and its variants more accessible to the average consumer. Manufacturing processes became increasingly automated, leading to improved efficiency and reduced production costs.

The consumer preferences during the late 20th century further shaped the trajectory of paint and texture manufacturing. With a growing awareness of interior design and the significance of color psychology, homeowners began opting for hues and finishes that reflected their personal styles. The demand for environmentally friendly options also started gaining traction as consumers became more conscious of sustainability. This pivotal change encouraged manufacturers to innovate and develop eco-friendly formulations, aligning with the objectives of modern consumers.

Moreover, the 1990s saw the liberalization of the Indian economy, exposing the Indian paint industry, including the companies in Gujarat, to international competition. This resulted in an influx of global brands, which pushed local manufacturers to enhance product quality and explore new formulations, such as texture paints and specialty coatings. As a result, Gujarat’s paint and texture manufacturing sector became increasingly competitive, fostering a rich tapestry of innovation that continues to thrive today.

Types of Paints and Textures Manufactured

Gujarat is a leading hub for paint and texture manufacturing, showcasing a diverse range of products that cater to both interior and exterior applications. One of the prominent categories includes interior paints, which are designed to provide aesthetic appeal and durability within homes. These paints often come in various finishes, such as matte, satin, and gloss, allowing homeowners to customize their spaces according to personal preferences. Notably, mithila home paint offers a variety of shades and textures that can elevate indoor environments, ensuring that each room reflects the desired ambiance.

Exterior paints, on the other hand, are engineered to withstand environmental challenges, including UV rays, moisture, and temperature fluctuations. These products typically possess water-resistant properties and are available in both emulsions and enamels. Emulsions are favored for their easy application and quick drying times, making them ideal for large-scale projects. Conversely, enamel paints are known for their durability and glossy finish, making them suitable for surfaces that require robust protection against external elements.

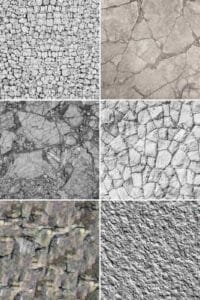

In addition to the standard paint categories, Gujarat also offers specialty coatings that cater to specific needs. These can include anti-fungal paints, heat-reflective coatings, and stain-resistant finishes, each designed to provide enhanced functionality alongside aesthetic appeal. The expanding market for unique texture finishes is also worth mentioning, with options such as stucco and plaster gaining popularity.

These materials not only add depth and character to walls but also serve practical purposes in improving insulation and moisture resistance. Innovative designs, including textured sprays and patterned finishes, have emerged, further enriching the artistic possibilities for personalizing home interiors. The combination of various paints and textures available in Gujarat, particularly mithila home paint, highlights the region’s commitment to quality and creativity in the home décor industry.

Raw Materials and Manufacturing Processes

The production of high-quality home paint, such as the renowned mithila home paint, hinges heavily on the selection of appropriate raw materials. Key ingredients in the formulation include pigments, solvents, and additives. Pigments are crucial as they provide the desired color and opacity; they can be organic or inorganic, each imparting different attributes to the final product. Solvents, which dissolve the pigments and resins, play an essential role in achieving the right viscosity for application. Common solvents include water, turpentine, and various organic compounds, selected based on their evaporation rates and environmental considerations. Meanwhile, additives enhance specific properties of the paint, such as drying time, adhesion, and resistance to mold or mildew.

The manufacturing processes involved in paint production are varied and depend on the desired characteristics of the final product. Typically, the process begins with the dispersion of pigments and fillers into a mixture of solvents and resins, facilitated by high-speed mixers or grinding mills. This step is crucial in ensuring a uniform mixture, which impacts the paint’s smoothness and application ease. Once blended, the mixture is subjected to further quality control measures, including viscosity tests and color matching processes, to guarantee consistency with the established standards.

After thorough mixing, the paste is processed through multiple stages, including milling, which finely grinds the components for a smoother texture. Additionally, the filling and packaging processes are automated, using machines that safely handle the liquid and ensure efficient assembly line production. To maintain the integrity and safety of the mithila home paint, rigorous quality control protocols are implemented throughout production, including testing for heavy metals and compliance with environmental regulations. These practices not only uphold product quality but also contribute to the sustainability of the manufacturing process.

Sustainability and Eco-Friendly Innovations

The paint industry in Gujarat is increasingly recognizing the importance of sustainability in its manufacturing processes. A significant shift towards eco-friendly practices and innovations has been observed, aimed at minimizing environmental impact while ensuring product safety for consumers. Manufacturers are actively exploring methods to reduce waste and utilize sustainable raw materials in the production of paints, including options like mithila home paint, which prioritize both quality and environmental responsibility.

One of the notable initiatives involves the sourcing of raw materials that come from renewable resources. This approach not only contributes to reduced carbon footprints but also promotes the uses of substances that are less harmful to the environment. Many companies are adopting natural pigments and additives in their formulations, transitioning from traditional chemicals. This transformation not only enhances the sustainability of products like mithila home paint but also elevates their appeal in environmentally conscious markets.

Moreover, manufacturers in Gujarat are developing low-VOC (volatile organic compounds) paints that emit fewer toxic emissions, providing a safer alternative for indoor environments. This innovation is essential for improving air quality and promoting the health and wellbeing of consumers. Such eco-friendly formulations are gaining traction in both residential and commercial sectors, reflecting a growing demand for sustainable living solutions. Additionally, some companies are implementing recycling programs for paint containers, ensuring that waste is minimized throughout the product lifecycle.

In conclusion, the paint industry in Gujarat is making remarkable strides towards sustainability. Through the adoption of eco-friendly practices, the use of sustainable raw materials, and the production of low-VOC paints, manufacturers are setting a precedent for responsible and innovative approaches to home paint solutions, including versatile offerings like mithila home paint. These advancements illustrate the industry’s commitment to creating a more sustainable future, balancing consumer needs with environmental stewardship.

Challenges Facing the Home Paint and Texture Industry

The home paint and texture industry in Gujarat faces a myriad of challenges that affect manufacturers’ operational efficiencies and profitability. Chief among these is intense competition within the market. A plethora of local and international brands are vying for consumer attention, driving innovation and pushing prices down. Small to medium-sized manufacturers often find it difficult to carve out a niche in such a saturated space, compelling them to reassess their marketing strategies and product offerings. In response, many companies are investing in unique product features and enhancing customer service to differentiate themselves from competitors.

Another significant impediment is the fluctuating prices of raw materials essential for producing quality mithila home paint. Global supply chain disruptions and geopolitical events can lead to unexpected spikes in costs, which directly impact profit margins. To mitigate these risks, some companies are exploring long-term contracts with suppliers or diversifying their sources of raw materials to ensure stability. Additionally, the rise in demand for eco-friendly and low-VOC (Volatile Organic Compounds) paints often requires manufacturers to invest in research and development to adapt their offerings, presenting both a challenge and an opportunity.

Regulatory hurdles also pose challenges for the industry. Compliance with environmental standards and regulations often demands significant investment, and failing to meet these requirements can lead to hefty penalties and lost market access. As such, manufacturers must not only keep abreast of evolving regulations but also invest in sustainable practices. Furthermore, changing market dynamics due to shifting consumer preferences necessitate a greater emphasis on innovation. Companies are adopting agile methodologies in product development to respond swiftly to market trends, ensuring they remain competitive in an ever-evolving landscape.

Market Trends and Consumer Preferences

The home paint and texture industry in Gujarat has witnessed significant transformations in recent years, influenced by various trends and evolving consumer preferences. One notable trend is the rise of DIY (Do It Yourself) projects. Many homeowners are now taking a hands-on approach, opting to undertake painting and decorating tasks themselves. This shift has been fueled by the availability of online resources, such as tutorials and videos, that empower consumers to execute their home improvement ideas independently. Consequently, manufacturers have started offering more user-friendly products, including cushions and tools specifically designed for DIY enthusiasts.

Another factor shaping consumer choices in the home paint market is the pervasive impact of social media. Platforms such as Instagram and Pinterest have emerged as powerful influencers, with users sharing their personalized color palettes and innovative designs. This visual culture has encouraged consumers to experiment with bold and unconventional shades, steering manufacturers to expand their color offerings. The demand for vibrant hues and unique finishes is prompting suppliers, including those dealing in mithila home paint, to innovate and stay attuned to current aesthetic trends.

Additionally, the growing interest in smart paints is revolutionizing how consumers perceive home painting. Smart paints, which possess features such as pollution control, thermal regulation, and self-cleaning properties, are gaining traction among environmentally conscious buyers. As awareness around sustainability and health issues heightens, there is a marked trend towards eco-friendly and technologically advanced products. The manufacturing sector is responding to this demand by investing in research and development to create innovative solutions that meet the expectations of modern consumers.

Overall, the interplay of DIY enthusiasm, social media influence, and the demand for smart paints suggests that the home paint market in Gujarat is evolving rapidly. Manufacturers will need to continuously adapt to these trends and preferences to capture the attention of discerning buyers who are increasingly seeking quality and innovation in their home décor choices.

Export Potential and Global Market Opportunities

The paint and texture manufacturing industry in Gujarat is poised for substantial growth, particularly when considering global export trends. The state’s reputation for high-quality products, such as mithila home paint, has positioned it as an attractive supplier for international markets. As countries increasingly seek vibrant and durable paint options, Gujarat can leverage its advanced manufacturing capabilities to meet this demand.

Key export destinations for Gujarat’s paint products include the United States, Europe, and the Middle East. These regions are experiencing a robust demand for decorative and functional paint solutions, including mithila home paint, which is favored for its aesthetic appeal and environmental sustainability. The wide array of colors and textures available allows designers and architects in global markets to create unique spaces, making sourcing from Gujarat an appealing option.

Furthermore, the trend towards eco-friendly and zero-VOC (volatile organic compounds) paints presents an opportunity for local manufacturers to innovate. By developing products that align with these global standards, Gujarat’s paint industry can capture the attention of conscious consumers abroad. The integration of traditional techniques with modern technology in producing mithila home paint also presents a unique selling proposition, enriching the cultural narrative around the products.

Local manufacturers must focus on establishing strong distribution networks and partnerships to fully capitalize on these global market opportunities. Participation in international trade fairs and exhibitions can enhance visibility and open avenues for business collaboration. By enhancing the brand image and promoting the rich heritage of Gujarat’s paint industry, local businesses can tap into the growing global demand for quality paint products, ensuring that the sector not only flourishes domestically but also establishes a significant footprint in the international market.

Future Outlook for Home Paint and Texture Manufacturing in Gujarat

The home paint and texture manufacturing industry in Gujarat is poised for significant evolution over the next decade, driven by technological advancements and shifting consumer preferences. With the increasing importance of sustainability, manufacturers are anticipated to adopt eco-friendly materials and practices in response to growing environmental concerns. Innovations in formulations, such as low-VOC and water-based paints, are expected to gain traction, reflecting a broader commitment to health and sustainability in residential interiors. Furthermore, the rising demand for unique textures and finishes will propel the industry towards more varied product offerings.

Another pivotal trend is the integration of digital technology within the manufacturing process. The implementation of automation and smart manufacturing techniques will streamline production, enhance quality control, and reduce operational costs. Additionally, digital tools for color visualization and design are becoming increasingly vital, allowing consumers to preview and select paint colors and textures more effectively. This technological incorporation is likely to cater to the evolving expectations of the modern consumer, who seeks both convenience and customization in their home paint solutions.

The market outlook also indicates a potential increase in market share for manufacturers specializing in niche products. The rise of the DIY segment, fueled by social media influences and home improvement trends, presents opportunities for companies that cater to individualistic preferences and offer a wide range of DIY-friendly paints and textures. Companies leveraging social media platforms for marketing and community engagement are likely to dominate in this space, influencing purchasing decisions and brand loyalty. Additionally, partnerships with interior designers and contractors will enhance visibility and facilitate access to broader customer segments.

In conclusion, the future of home paint and texture manufacturing in Gujarat is bright, characterized by innovation, sustainability, and a responsiveness to market trends. By embracing these changes, producers can effectively navigate the challenges and opportunities that lie ahead, ensuring a vibrant and competitive industry landscape.